1

Need ideas for fitting SS brake line to rear master cylinder Mon Oct 06, 2014 11:36 pm

Need ideas for fitting SS brake line to rear master cylinder Mon Oct 06, 2014 11:36 pm

robmack

Life time member

Hi,

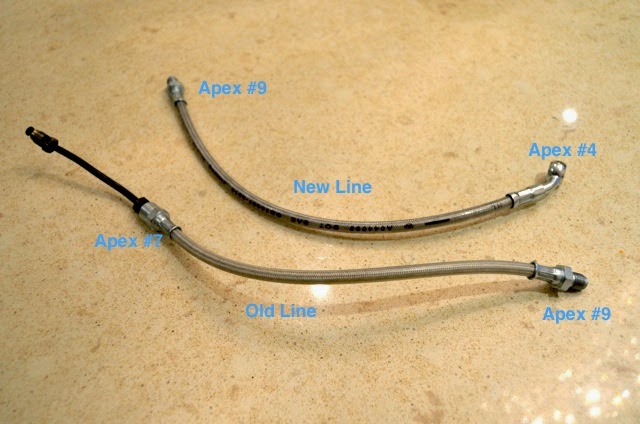

I had a new brake line made up for my K75 rear brake (non-ABS). One end is a straight fitting that mates to the rear master cylinder and the other is a 45 degree banjo that bolts up to the rear calliper. When I thread the straight onto the MC, the banjo is wrong way around, meaning that I have to put a twist into the flexible line to make the banjo match up. This is a result of the banjo being crimped to the line 180 degrees out (and I can't rotate the banjo fitting on the line). I would need to add 1/2 turn to the straight fitting to make it work but that would require me to over-torque the fitting and risk ruining the master cylinder threads.

I need a way to torque up the straight fitting to align the banjo properly. I have two ideas but am soliciting for more:

1. insert a crush washer into the outlet of the MC. The crush washer would raise the level where the fitting mates, allowing me to correctly adjust the brake line. I don't know if putting a washer in the MC is a good idea, especially if it gets jammed.

2. file off the end of the straight fitting so that it screws deeper into the MC port

Can anyone tell me which of these is best? Is there a better way to get this accomplished? These are brakes after all and I'm wary that I get the safety things right on the bike.

I had a new brake line made up for my K75 rear brake (non-ABS). One end is a straight fitting that mates to the rear master cylinder and the other is a 45 degree banjo that bolts up to the rear calliper. When I thread the straight onto the MC, the banjo is wrong way around, meaning that I have to put a twist into the flexible line to make the banjo match up. This is a result of the banjo being crimped to the line 180 degrees out (and I can't rotate the banjo fitting on the line). I would need to add 1/2 turn to the straight fitting to make it work but that would require me to over-torque the fitting and risk ruining the master cylinder threads.

I need a way to torque up the straight fitting to align the banjo properly. I have two ideas but am soliciting for more:

1. insert a crush washer into the outlet of the MC. The crush washer would raise the level where the fitting mates, allowing me to correctly adjust the brake line. I don't know if putting a washer in the MC is a good idea, especially if it gets jammed.

2. file off the end of the straight fitting so that it screws deeper into the MC port

Can anyone tell me which of these is best? Is there a better way to get this accomplished? These are brakes after all and I'm wary that I get the safety things right on the bike.

__________________________________________________

Robert

1987 K75 @k75retro.blogspot.ca